Polybond Ltd, Unit 6, William Street, Northam, Southamton, Hampshire, SO14 5QH, United Kingdom

Tel: 02380 988350 Fax: 02380 988355 sales@polybond.co.uk

Hypalon

Product Function

Hypalon

is a solution of chlorosulphonated polyethylene, pigmented to various colours.

Uses

Hypalon

is

a

Protective

coating

that

is

resistant

to

most

industrial

chemicals

and

is

ozone

proof.

Hypalon

is

a

Non

combustible

coating

that

retards

the

spread

of

flame

to

a

combustible

substrate.

Hypalon

has

an

exterior

reflective

coating

for

protection

against

sunlight

that

will

not

fade

or

discolour.

Hypalon

has

a

flexible

coating

for

non-rigid

substrates where a conventional coating would be too brittle.

Substrates

Hypalon

can be used on Metal, Concrete, Timber, Rubber, Cork or Fibrous Compositions.

Although

Hypalon

coating

will

adhere

readily

to

most

surfaces,

certain

substrates

require

the

application

of

a

primer to improve adhesion.

General Preparation

All surfaces must be clean, dry and free from dust and grease, oil or any substance that could impair adhesion.

Application

By brush or roller. Apply a generous coat. Allow film to form. Do not brush out.

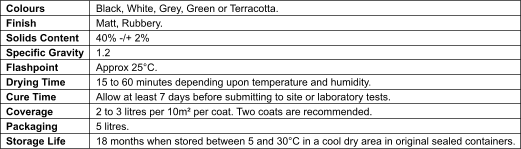

Properties

Health and Safety

Hypalon

has

a

flash

point

of

appoximately

25°C

and

should

only

be

used

well

away

from

possible

sources

of

ignition.

Skin

contact

should

be

avoided

and

attention

must

be

given

to

industrial

hygiene.

Extraction

of

vapours

and

fire

precautions

must

be

taken.

Personnel

must

be

informed

of

any

handling

requirements

especially

when

using the product indoors

The claims in this leaflet were believed to be correct at the time of going to press and made in good faith based on exhaustive tests carried out

over a long period. Polybond Ltd and their agents cannot, however, accept responsibility for the behaviour of the material(s) in any individual

case, and potential users are advised to check this information is still applicable and that the product(s) are suitable for their intended use.