Furnascote Non Vit

Improving Power Station Efficiency

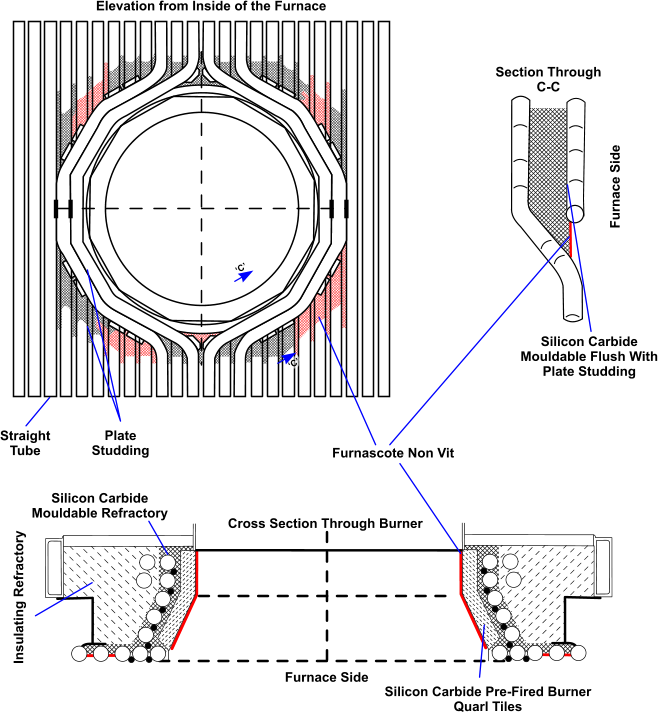

A Modern Burner Quarl

Furnascote Non Vit can improve power station efficiency by increasing the life of

burner quarls and reducing down time.

Large modern burners benefit as much as older designs

PRODUCT FUNCTION

Furnascote Non Vit acts as a protective coating on silicon carbide pre-fired quarl tiles and surrounding areas

and guards against the effects of vanadium pentoxide attack.

PREPARATION

Any large build up of slag will be carefully removed from the burner throats. Small areas can be left if firmly

adhered and is not detrimental to the setting. If the remaining slag is glazed, it will be roughened up with an

abrasive wheel to give a key. All remaining loose particles and dust will be removed.

APPLICATION

A 1mm brush coat of Furnascote Non Vit will be applied filling in any cracks or voids. Allow to dry for 30 minutes

before the application of a second coat which will be applied by trowel to a finished thickness of 3mm. The

second coat will be trowelled to a smooth finish.

DRY OUT AND BAKE IN

The finished throats will be left to air dry for 48 hours. They will then be slowly heated at 250°C / hour up to

1500°C gas temperature where it will be held for 5 hours. The heating cycle will continue with a steady

temperature rise over the next 48 hours up to the maximum furnace temperature.

When coming off load the refractories should be allowed to cool naturally.

HEALTH AND SAFETY

Handle with care, Observe all safety labels on packaging and paint containers, for more details see our Material

Safety Data Sheets.